Manufacturing plants convert raw material into a final product. Think of cars, where the production line consists of a large number of phases to put all the different parts together into a working car. Big machines in such a plant perform the processing steps in different phases, which often have to be done in a specific order.

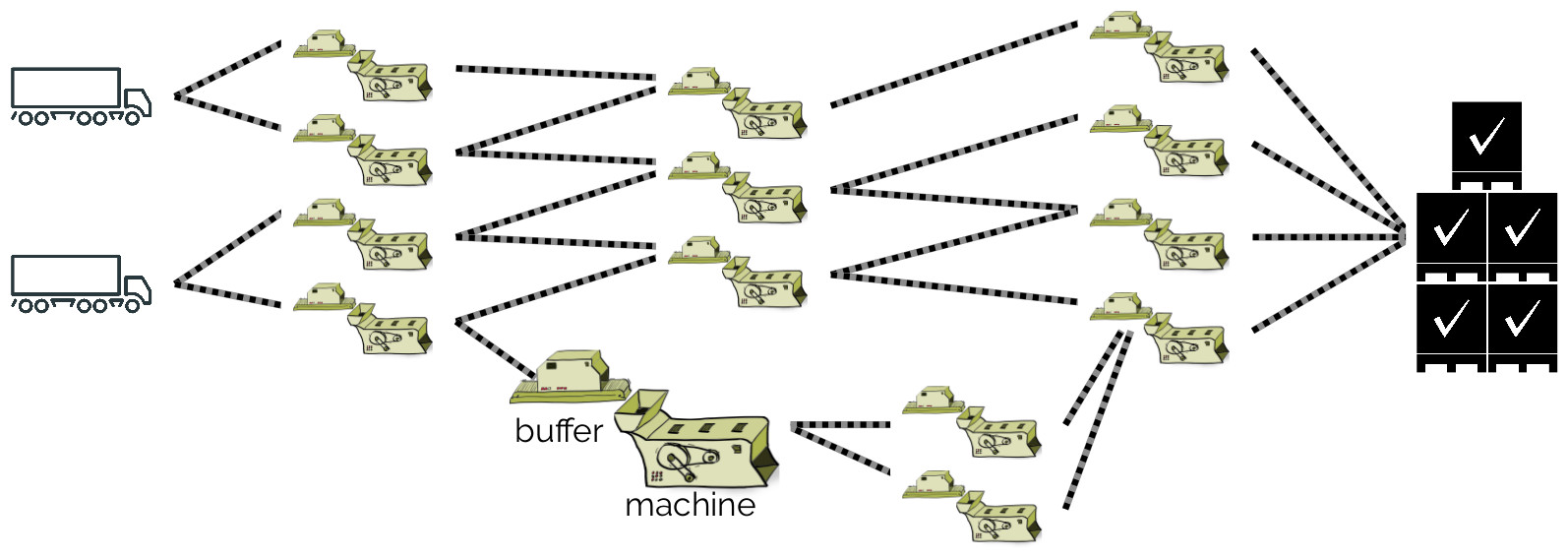

In between the phases, the products are stored in buffers where they wait for the next processing step. This is an expensive part of the production, as storing in buffers costs space and money. Each of the machines is dedicated to a particular buffer, and hence also a particular processing phase. An example of the schematic layout of the production process in a manufacturing plant is the one depicted in the figure below.

A possible layout of a manufacturing plant.

Designing a manufacturing plant is an immensely complicated task, certainly for large production lines. Companies wish to make these production phases as cheap as possible. This has many aspects. For instance, designers should make sure that there will not be too many products waiting for too long in one of the buffers. Indeed, there is only limited storage space, and in some cases, products may perish while waiting. At the same time, the designer needs to limit the number of machines to be used because of economic considerations. Furthermore, he or she needs to make sure that the workload is spread evenly over the machines. This is not easy, since the time needed to complete the different processing phases may differ. The designer needs to decide what number of machines he or she needs to assign to every processing phase, and given a particular assignment of machines to processing phases, how long a product will have to wait on average in a particular buffer. Such questions are often very hard to answer.

So, how can one efficiently design a complex manufacturing plant?

The key to success: Queueing networks

It helps to realize that the production process essentially consists of waiting periods of products in a buffer (or queue), followed by processing periods by a machine after leaving the buffer. Thus, with some imagination, a manufacturing plant can be seen as an interconnected set of queues, where products wait in a queue, are then processed by the machine at the head of the queue, and subsequently move on to the next queue. Such connected sets of queues are called queueing networks. The scientific branch of ‘queueing theory’ may help the designer. Indeed, in the scientific literature, much attention has been given to queueing networks from a mathematical perspective. In fact, since the 1950s, many scientific papers have been written with the goal of answering questions like the ones mentioned above. However, the queueing networks encountered in manufacturing plants have a feature that has so far hardly been studied in the scientific literature. In upcoming articles, we will take a closer look at these special queueing networks, and find possible ways of analysing them.